Metal sheet processing equipment design and manufacturing enterprise

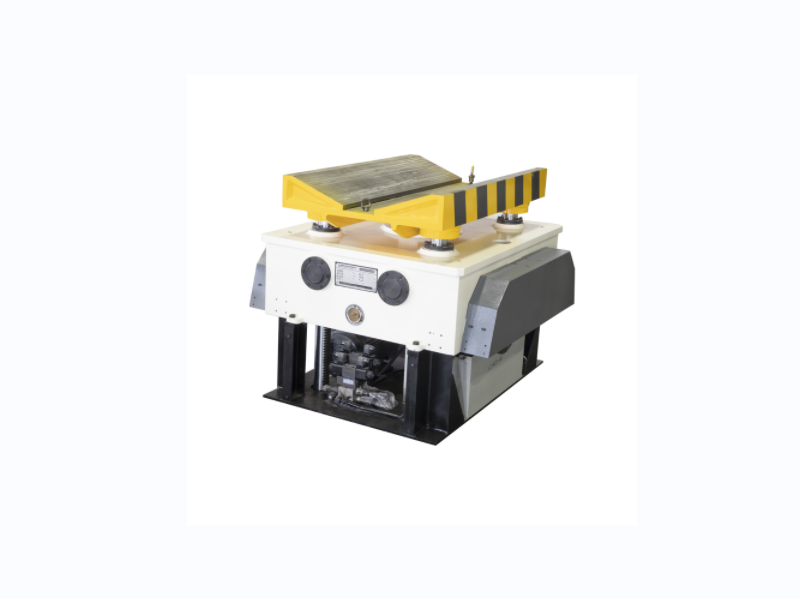

Metal sheet processing equipment design and manufacturing enterpriseXHV80P-2

I. Overview

1.1, this unit is used for tinplate and aluminum coil unwinding, leveling, waveform shearing special equipment. It is an important equipment to effectively reduce material loss and production cost in the industry of tin printing and lid making. The waveform cutting equipment can save 3-8% of materials.

1.2. The wave shearing production line is composed of uncoiling machine parts, levelling machine parts, wave shearing machine parts, belt conveying parts, receiving table, electrical control cabinet, etc. The same equipment can be used to cut different waveforms, with a shearing frequency of 80 times/min.

1.3. The equipment can be randomly selected between single, double and triple collection.

Ii. Main technical parameters of the unit

2.1. Shear thickness: 0.15 ~ 0.5mm;

2.2. Shear width: 600 ~ 1200mm;

2.3. Shear length: 460 ~ 1200mm;

2.4. Cutting times: 80 times/min (when the cutting length is 800mm);

2.5. Design speed: 80m/min;

2.6. Bearing capacity of receiving table: 2t;

2.7. Receiving height: 460mm(including bracket);

2.8. Shear length error: ≤±0.15mm/m;

2.9. Shearing diagonal error: ≤±0.15mm/m;

2.10. Uncoiler expansion shaft diameter range: φ380 ~ φ420mm(coil inner diameter φ405mm);

2.11. Maximum diameter of coil: φ1800mm:;

2.12. Maximum weight of rolling material: 13.5t;

2.13. Installed capacity: about 45kW;

2.14. Production line area: about 15.0×5.0 meters.

2.15. Power requirements: three-phase five-wire system 380V±5%, 50Hz±2Hz.

2.16. Air source requirements: Provide air source with prepared pressure of 0.6MPa and flow rate of 1m3/min.

2.17. Hydraulic oil requirements: L-HM46 hydraulic oil shall be provided in the oil cylinder.

2.18. Gear oil requirements: 220# gear oil shall be provided in the gear box of the leveler.

2.19. Working environment temperature: -10 ~ 40℃.

2.20. Working environment relative humidity: ≤ 80% (no condensation).

Related Products

cnxhkj@vip.163.com

cnxhkj@vip.163.com +8618056308262

+8618056308262 +8618056308286

+8618056308286